Boosting Thermal Efficiency with Gas-Filled Insulating Glass Units

As codes, standards and green building certification programs governing energy use and carbon reduction requirements become stricter and stricter, building owners and architects are actively seeking energy efficient, insulating glass units (IGUs) for their building designs.

Designed to keep buildings warmer in the winter and cooler in the summer, a standard IGU is two lites of glass separated by an air filled space. For enhanced insulating values, low-e coatings and/or three lites of glass can be specified.

To boost performance even further, architects and designers can choose glass systems that incorporate a noble gas between the panes of glass instead of air. Because these gases like argon or krypton are denser than air, there is less heat transfer through the IGU.

When 90% argon gas-fill is used in a low-e IGU instead of air, the window’s insulating value can improve by up to 16% and krypton can increase insulation by up to 27%.

However, krypton filled IGUs are not available on a large enough scale to meet market needs. This is due to the scarcity of the gas itself which is reflected in its pricing – as much as 40 times the cost of argon gas. For these reasons, krypton is not a practical option.

With argon and krypton, partial pressure differentials between the air outside and the gas inside the glass panes cause the gas to escape out of the IGU over time. However, this occurs at a low rate. Furthermore, the rate of loss slows as argon escapes due to reducing partial pressure difference, thereby making the impact on performance essentially negligible for the service life of most IGUs.

Running the Numbers

To ensure these gas-filled units are fabricated correctly, IGUs should be third-party certified and tested per ASTM E2188/E2190 Standard Specification for Insulating Glass Unit Performance and Evaluation. This test measures the amount of argon gas fill before and after the equivalent of 10 years of weathering. To pass the test, units are permitted to lose up to 10% of their gas for an average of 1% per year.

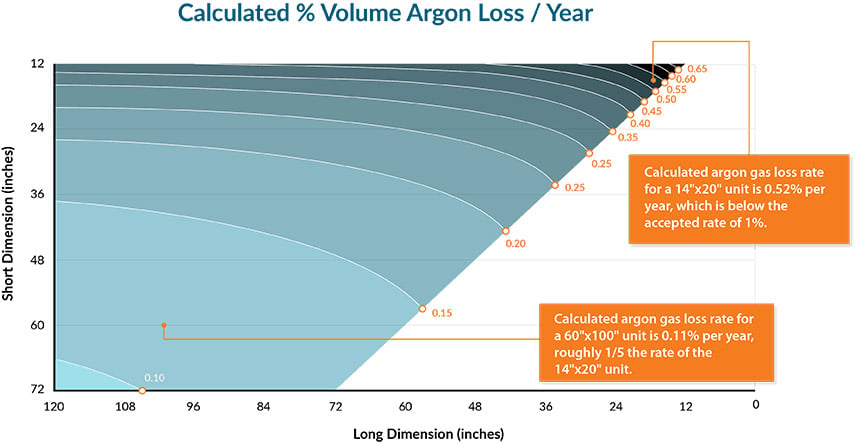

However, it is important to point out that the test specimen size is quite small at 14 inches by 20 inches, whereas the average gas-filled IGU installed in a commercial building is much larger – 60 inches wide by 100 inches tall.

In running the computation per Dalton’s law of partial pressures, the actual gas loss rate per year for a dual IGU with a 100% metal spacer, ½ inch-wide argon space and 0.015-inch thick by 0.140-inch wide polyisobutylene (PIB) primary seal comes out to be significantly less than 1%.

This pressure differential in the unit vs. the atmosphere is based on an IGU with 90% argon, 7.8% nitrogen and 2.1% oxygen vs. the outside air with 78% nitrogen, 21% oxygen and 1% argon. The calculation also assumes infinite moisture vapor permeability of the IGU secondary seal with no PIB primary seal deformation.

Taking an argon-filled IGU and tabulating the calculation for gas loss given a PIB moisture vapor transmission rate of 89 cc∙mm/m2∙day∙atm at 86°F, the gas loss per year for a 14 inch by 20 inch unit is 0.52%, which is well below the accepted rate of 1% and is in line with typical ASTM E2188/E2190 test results. However, when computation is made for a 100 inch by 60-inch unit, the loss rate is much lower at 0.11% per year or approximately one fifth of the rate of the smaller unit.

It should be noted that high quality workmanship is required to produce IGUs with low argon gas loss rates. Characteristics of high-quality workmanship include, but are not limited to:

- Selecting the proper quantity of sealant.

- Sealant pressed out to the proper width and thickness around the entire perimeter including the corners.

- Continuous sealants, with no gaps, around perimeter of IGU.

- Fully sealed corners and corner keys and splice joints.

- Good adhesion of sealants to the glass and spacer.

- Proper quantity of active desiccant.

- No dirt or debris in the sealant line or in the airspace.

- Clean, undamaged glass and properly edge deleted if the unit is low-e coated.

To help ensure that these high quality standards are met, Vitro Certified® Network Fabricators must go through regular and rigorous audits, including compliance with the ASTM E2188/E2190 testing protocol. That said, the fabricator is ultimately responsible for the quality of their finished IGU products.

Quality Assurance

In sum, properly fabricated units register an almost negligible annual loss of argon. Consequently, specifiers can be confident in the long-term insulating performance of argon-filled IGUs armed with a more detailed understanding of these minimal gas loss calculations coupled with rigorous quality control standards.

This is particularly important as codes and standards like the International Energy Conservation Code (IECC) and American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) 90.1, are requiring stricter insulation values.

For more information or other glass questions, please contact Vitro or call 1.855.VTRO.GLS (1.855.887.6457).

Click image to enlarge