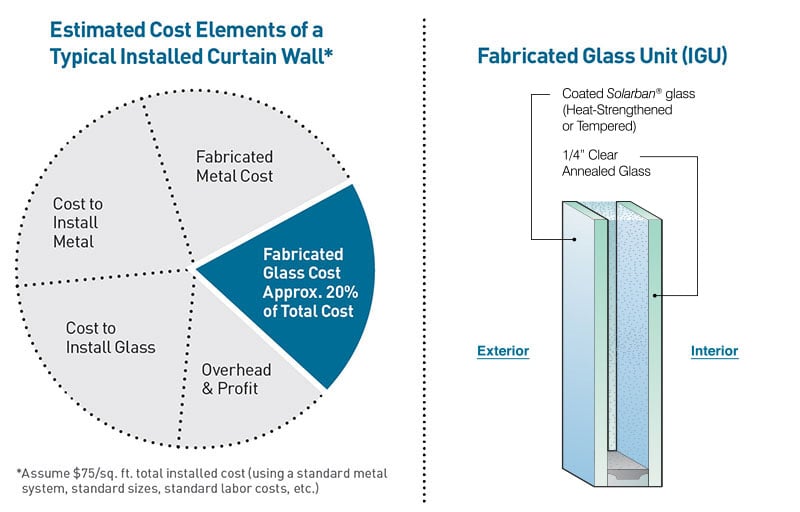

To make more informed decisions in the evaluation, selection and specification of architectural glass products, Vitro Architectural Glass (formerly PPG glass) recommends using an installed systems cost approach. The pie chart below indicates the approximate cost percentage of fabricated glass relative to a typical installed curtain wall total cost. The table, “Fabricated Glass Options,” indicates the relatively minor cost impact of selecting various Solarban® solar control low-e coated glasses by Vitro glass on the overall installed cost.

Fabricated Glass Options

|

1/4" SOLARBAN® glass and 1/4" clear inboard lite |

Est. Add’l. % Cost Impact to Installed Curtain Wall Cost |

|

Solarban® 60 Glass & Tints |

Ranges from 0-7%. Consult with your |

Fabricated Glass Cost Considerations

Architectural designs can be a significant driver of glass cost. Total fabricated glass costs can be significantly impacted by unit designs (square footage and aspect ratio), unit quantities (total units and number of unique sizes) and glass fabrication yield losses due to cutting, tempering, heat-strengthening and laminating. Special considerations such as frit or etched glass, spandrel glass, non-rectangular or oversized units and glass thickness can also substantially impact fabricated glass costs.

Glass Selection Conclusions

Selecting the proper high-performance Solarban® glass by Vitro Glass product for your project can provide improved solar and thermal performance, increased occupant comfort, reduced HVAC investment and enable a broad spectrum of design aesthetics.

The total installed cost impact of upgrading to various Solarban® glass coatings—whether on clear, Acuity® glass, Starphire Ultra-Clear® glass, or tinted glasses by Vitro Glass—is minimal and represents, on a standard project, typically a 5-7% additional cost impact.

For architectural glass support, contact your Vitro Architectural Glass Architectural Manager or a vitroglazings.com Architectural Services representative at 1.855.VTRO.GLS (1-855-887-6457).

Note: The cost estimates depicted in this article have been developed based on input from industry-leading glass fabricators and glazing contractors and are generally indicative of market factors and conditions. The estimates shown are based on national averages and your actual cost may vary based on local factors. Vitro glass is not responsible for the accuracy of such estimates.

Updated on August 12, 2024