When it comes to windows, homeowners are familiar with the parts of windows they can see, like the glass, the frame and the hardware. However, there are parts of the window inside the glass that play a crucial role in its performance.

Every window unit is comprised of two (or sometimes three) panes of glass separated by a spacer that holds the panes together, creating an insulating space where air or a safe gas, such as argon or krypton, can be added to protect the home from heat loss and the outside elements.

Spacers are a critical part of every window unit. They separate the panes of glass, providing the insulating glass unit within the window with structural integrity along with a thermal and moisture seal that enhances the window’s thermal performance. Window spacers are available in either foam or stainless steel. Of the two types of spacers, stainless steel spacers provide the most value and significantly contribute to the window’s thermal performance, aesthetics and durability.

Thermal Performance

One of the primary indicators of a high-quality window is its ability to keep block cold air in the winter and hot air in the summer. This is known as thermal performance, and window spacers play a very important role in a window’s ability to perform.

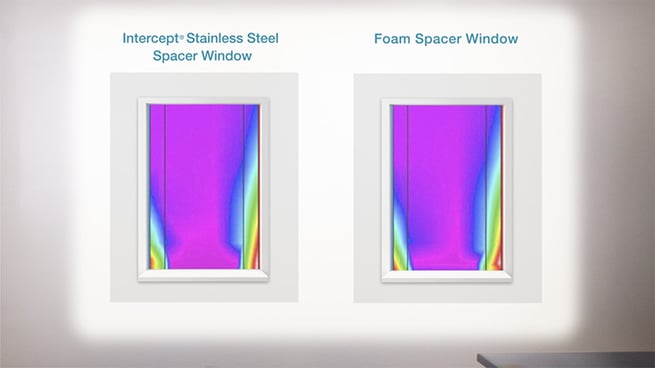

Studies of the thermal performance of windows with stainless steel spacers versus those with foam spacers reveal that stainless steel spacers perform just as well as foam alternatives.

Photos of different window glasses were taken using a thermal imaging camera, which can indicate hot and cold spots on a material. The image on the left is a window with a stainless-steel spacer, while the image on the right is a window with a foam spacer. There is no clear difference in the temperature of the windows, indicating that stainless steel spacers help block the elements just as well as foam spacers.

Additionally, when the U-factors (or insulating characteristics) of the glasses are measured, both are equal to three places beyond the decimal point.

Strength and Aesthetics

In addition to its impact on a window’s thermal performance, the spacer's strength also can contribute to the overall aesthetics of the window and make it more attractive.

Inside a typical double pane window, a stainless steel spacer can support upwards of 500 grams of weight without budging. However, a foam spacer cannot support more than 200 grams of weight without tearing or dislodging.

While stainless steel can clearly support more weight, it’s also important to understand the impact that strength has on window aesthetics. Due to its U shape and its strong seal, steel spacers sit tight between the two panes of glass and give the window a crisp, clean look with uninterrupted sight lines. Because foam is a more pliable material, it does not always sit straight inside the panes of glass and can result in an undesirable wavy appearance, interfering with the sightlines of the window. Therefore, stainless steel spacers are not only stronger than the foam spacers, but also more aesthetically pleasing.

Durability and Gas Retention

Windows need to be able to stand the test of time and endure daily pressure changes that may lead to gas leaks.

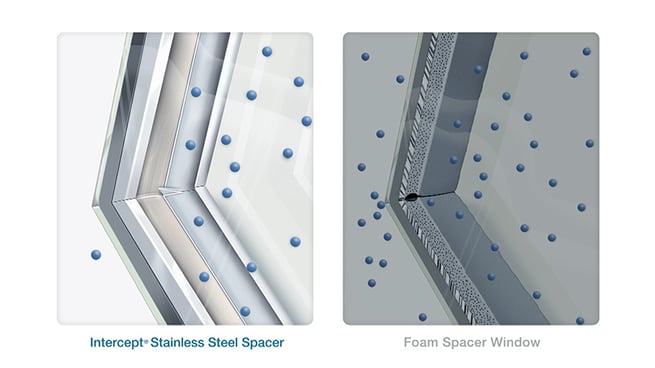

The spacers used in double or triple pane window are designed to keep air or invisible insulating gas, such as argon or krypton, contained inside the window. However, gas molecules naturally look for any place to escape, especially at the corners. With stainless steel spacers, a special sealant is used to bond the metal spacer to the edges of the glass to create a tight seal. As a result, the continuous metal and sharp bent corners combine with the sealant to provide a strong moisture and vapor barrier that prevents the air or gas from escaping.

When a foam spacer is used, it will often be placed in between the glass by hand and can lack structural integrity, especially at the corners. To combat this, a sealant is used to hold the foam spacer in place, but over time, the window's constant expansion and contraction leads to stress and separates the sealant from the spacer. This creates gaps for the gas to escape.

Additionally, foam spacers are naturally much more porous than stainless steel at a molecular level. Stainless steel is a much stronger material and is better suited to routine exposure to the elements.

Residential window fabricators and homeowners should be sure to consider the exceptional value and many performance benefits of stainless steel window spacers, which help maximize the thermal performance, strength, aesthetics, durability and gas retention of residential windows.

For additional information about residential window glass and stainless steel spacers, please visit vitrowindowglass.com.

For any other glass questions, please contact Vitro Glass or call 1-855-VTRO-GLS (1-855-887-6457).

Updated on March 2, 2022